Reactive PUR hotmelts

Reactive hotmelts are mainly used in industrial gluing processes, but increasingly also in skilled craft businesses. They enable extremely strong adhesive bonds and customized processes. No other adhesive system offers such a high degree of customizability. Reactive PUR hotmelts have gone through major developments over the past decades and are being used for more applications every day. There are practically no limits to their uses. In fact, applications that seem unimaginable today may well be realized with PUR hotmelts tomorrow.

Reactive PUR hotmelts are solid masses that are melted and applied while still fluid. The bonding strength is then consolidated in an ensuing two-stage physical-chemical process.

1. Physical

After the adhesive has been applied, it cools off and solidifies, leading to high to very high initial strength.

2. Chemical

The next step involves a chemically reactive hardening process. The adhesive reacts with the moisture either on or in the material to be bonded and with the moisture in the air. This results in a tightly cross-linked elastomer with mechanical properties ranging from highly elastic to highly rigid, depending on the formulation, that permanently bonds the materials. Once the reaction is completed, the adhesive cannot be remelted. The timing of the chemical reaction can be defined in the adhesive formulation, depending on the field of use.

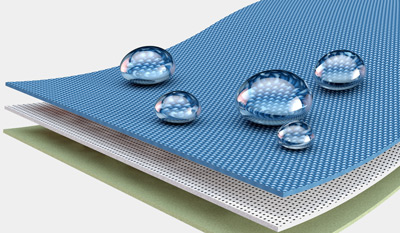

In some cases, if the material to be bonded is suitable, the hotmelt adhesive also reacts with the material’s solid components, leading not only to physical bonds, but to inseparable chemical bonds at atom level. This results in absolutely top-quality bonding. The adhesive properties and water and temperature resistance of reactive PUR hotmelts are hard to beat.

Demand for low-emission adhesive systems has risen sharply in recent years. ME adhesives are a good entry product into the world of reactive hotmelts. As hazard substance labelling no longer applies to them, they, like EVA and PO hotmelts, can be used for extraction and filter systems. Having identical adhesive properties to standard PUR hotmelts, ME hotmelts provide for safer and more environmentally-friendly manufacturing processes all along the line.

Our chemical engineers have been developing low-emission hotmelts for many years and can customize ME hotmelts for very specific uses – for the furniture industry, the building industry, the automobile sector, for filters, textiles, and much more. Nothing is impossible!

PUR adhesive systems based on sustainable, plant-based raw materials are becoming increasingly popular. The prerequisite is that the plant-based raw materials used are not suitable for food production. KLEIBERIT’s bio-based PUR hotmelts achieve exactly the same bonding results as the established PUR hotmelts.

Industries

Furniture

KLEIBERIT 706.0.05 Reactive hotmelt

- excellent running properties, sticks to a wide range of materials

- good surface properties

- surface lamination

- very suitable for thin papers and films

KLEIBERIT 706.0.09 Reactive hotmelt

- monomer-reduced

- great bonding to plastics

- FDA Guideline 21CFR § 175.105

- surface lamination

KLEIBERIT 706.1.00 Reactive hotmelt

- all-round adhesive with good initial strength

- IMO FTP Code Part 5 & Part 2

- surface lamination of materials with increased recoil strength (HPL, CPL)

KLEIBERIT 706.1.50 Reactive ME hotmelt

- surface lamination of high-gloss materials

- free of labeling

- IMO FTP Code Part 5 & Part 2

- general surface lamination

- high-gloss and super matt decors

- multiple uses in ship building

- gluing polystyrene, EPS, XPS, PUR and PIR to different cover materials

KLEIBERIT 706.2.50 Reactive ME hotmelt

- sticks to a wide range of materials

- free of labeling

- general surface lamination

KLEIBERIT 706.4.00 Reactive hotmelt

- very high initial strength

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, CPL

KLEIBERIT 706.4.50 Reactive ME Hotmelt

- IMO FTP Code Part 5 & Part 2

- surface lamination of materials with high restoring forces such as veneers, HPL, CPL

- impermeable materials

KLEIBERIT 706.4.54 Reactive hotmelt

- high initial strength

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, CPL

KLEIBERIT 706.7.00 Reactive hotmelt

- very high initial strength

- excellent adhesion to HPL

- surface lamination of cover materials such as HPL, CPL

KLEIBERIT 706.7.50 Reactive ME hotmelt

- excellent adhesion to HPL

- free of labeling

- surface lamination of cover materials such as HPL, CPL

- impermeable materials, e.g. HPL

KLEIBERIT 706.9.00 Reactive hotmelt

- very good wetting properties

- suitable for porous materials such as open-cell foams into which other adhesives sink

KLEIBERIT 707.9.00 Reactive hotmelt

- for industrial equipment with higher feeding speeds

- versatile edge banding on furniture boards (fronts, rear and base panels, sides)

KLEIBERIT 707.9.40 Reactive hotmelt

- highest possible initial strength

- ideal for CNC machines

- versatile edge banding on furniture boards (fronts, rear and base panels, sides)

KLEIBERIT 707.9.50 Reactive ME hotmelt

- free of labeling

- for industrial equipment with higher feeding speeds

- versatile edge banding on furniture boards (fronts, rear and base panels, sides)

KLEIBERIT 707.9.85 Reactive ME hotmelt

- no hazard labeling required, contains renewable raw materials

- for industrial equipment with higher feeding speeds

- versatile edge banding on furniture boards (fronts, rear and base panels, sides)

KLEIBERIT 709.1.00 Reactive hotmelt

- excellent adhesion to inorganic materials

- surface lamination of ceilings, acoustic ceiling elements

- surface lamination of mineral materials (e.g. stone veneers), metal, and glass

KLEIBERIT 709.1.50 Reactive ME hotmelt

- free of labeling

- general surface lamination

- with integrated adhesion promoter for metal surfaces

KLEIBERIT 709.3.00 Reactive hotmelt

- very high surface smoothness and quality

- high-gloss decors

- super matt decors

KLEIBERIT 711.0.52 Reactive ME hotmelt

- light-fast product

- surface lamination of transparent plastic films with suitable adhesion promoter on the adhesive side

KLEIBERIT 711.2.00 Reactive hotmelt

- plastics specialist

- surface lamination of various plastic films

KLEIBERIT 711.3.00 Reactive hotmelt

- for gluing diffusion-resistant materials

- high initial strength

- IMO FTP Code Part 5 & Part 2

- general surface lamination

KLEIBERIT 711.9.00 Reactive hotmelt

- long open time

- extremely high initial strength

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, etc.

- honeycomb plate panelling

KLEIBERIT 711.9.06 Reactive hotmelt

- for porous and pressure-sensitive materials

- very high initial strength

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, etc.

- honeycomb plate panelling

KLEIBERIT 711.9.50 Reactive ME hotmelt

- extremely high initial strength

- micro-emission

- long open time

- honeycomb plate panelling

- surface lamination of materials with high recoil strength, e.g. veneers, HPL

- surface lamination of ceilings, acoustic ceiling elements

KLEIBERIT 716.8.50 Reactive ME hotmelt

- product free of labeling

- plasticizer stable

- excellent bonding to plastics

- general surface lamination

- surface lamination of plasticized materials on carrier boards

Building and construction elements

KLEIBERIT 702.0.50 Reactive ME Hotmelt

- suitable for CompleteLine process

- free of labeling

- profile wrapping

KLEIBERIT 706.0.09 Reactive hotmelt

- monomer-reduced

- manufacturing sandwich panels

- gluing polystyrene, EPS, XPS, PUR and PIR to different cover materials

KLEIBERIT 706.0.37 Reactive hotmelt

- short open time

- for very short cycle times

- suitable for the production of household sponges

KLEIBERIT 706.1.50 Reactive ME hotmelt

- excellent surface properties

- free of labeling

- IMO FTP Code Part 5 & Part 2

- general surface lamination

- surface lamination of ceilings, acoustic ceiling elements

- high-gloss and super matt decors

KLEIBERIT 706.4.00 Reactive hotmelt

- very high initial strength

- manufacturing sandwich panels

- gluing polystyrene, EPS, XPS, PUR and PIR to different cover materials

KLEIBERIT 707.0.00 Reactive hotmelt

- high initial strength, suitable for pass-through machines

- 2-layer parquet boards

KLEIBERIT 709.1.00 Reactive hotmelt

- excellent adhesion to inorganic materials

- surface lamination of ceilings, acoustic ceiling elements

- surface lamination of mineral materials (e.g. stone veneers), metal, and glass

KLEIBERIT 711.2.00 Reactive hotmelt

- plastics specialist

- surface lamination of ceilings, acoustic ceiling elements

- surface lamination of various plastic films

KLEIBERIT 711.3.00 Reactive hotmelt

- for gluing diffusion-resistant materials

- high initial strength

- IMO FTP Code Part 5 & Part 2

- laminating aluminium sandwich elements

- surface lamination of ceilings, acoustic ceiling elements

KLEIBERIT 711.9.00 Reactive hotmelt

- long open time

- extremely high initial strength

- surface lamination of ceilings, acoustic ceiling elements

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, etc.

- honeycomb plate panelling

KLEIBERIT 711.9.06 Reactive hotmelt

- for porous and pressure-sensitive materials

- very high initial strength

- surface lamination of ceilings, acoustic ceiling elements

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, etc.

KLEIBERIT 711.9.50 Reactive ME hotmelt

- long open time

- extremely high initial strength

- surface lamination of ceilings, acoustic ceiling elements

- honeycomb plate panelling

- surface lamination of materials with high recoil strength, e.g. veneers, HPL

KLEIBERIT 716.4.00 Reactive hotmelt

- low dosing amounts possible

- non-stringing

- surface lamination of footfall sound insulation materials on laminates

- LVT surface lamination

KLEIBERIT 716.8.00 Reactive hotmelt

- excellent adhesion to PVC

- plasticizer stable

- surface lamination of photovoltaic elements

- surface lamination of LVT floors

- general surface lamination

KLEIBERIT 716.8.50 Reactive ME hotmelt

- product free of labeling

- plasticizer stable

- excellent bonding to plastics

- surface lamination of photovoltaic elements

KLEIEBRIT 716.4.50 Reactive ME hotmelt

- free of labeling

- low dosing amounts possible

- non-stringing

- surface lamination of backing materials

- Surface lamination of footfall sound insulation materials on laminates

Filters

KLEIBERIT 703.2.00 Reactive hotmelt

- medium open time

- low processing temperature

- FDA Guideline 21CGR § 175.105 und 177.1680

- food filters

KLEIBERIT 703.5.00 Reactive hotmelt

- low fogging level

- short open time

- good bonding to various plastic materials and metals

- fuel filters

- engine air filters

- AdBlue filter

KLEIBERIT 708.8.09 Reactive hotmelt

- long open time

- low processing temperature

- fulfills the food law requirements of the Regulation (EU) 10/2011

- gluing pleats and filter chambers

- industrial dust removal filters

Textiles

KLEIBERIT 701.0.00 Reactive hotmelt

- sticks to a wide range of materials

- high initial strength

- ECO Passport by OEKO-TEX®

- leisure and sportswear, work garments

- shoes

- roofing underlays

KLEIBERIT 701.4.00 Reactive hotmelt

- excellent resistance to hydrolysis and sterilization

- ECO Passport by OEKO-TEX®

- functional textiles

- medical products

KLEIBERIT 701.6.03 Reactive hotmelt

- sticks to a wide range of materials

- shoes, leisure and sportswear, work garments

KLEIBERIT 701.7.30 Reactive hotmelt

- very high initial strength

- ECO Passport by OEKO-TEX®

- shoes, leisure and sportswear, work garments

- roofing underlays

KLEIBERIT 716.8.50 Reactive ME hotmelt

- product free of labeling

- shoes, leisure and sportswear, work garments

- functional textiles

KLEIBERIT 725.3.00 Hotmelt

- low processing temperature

- roofing underlays

White goods

KLEIBERIT 706.0.00 Reactive hotmelt

- elastic glue joint

- high initial strength

- no blistering

- table top gluing for white goods

Ship and boat building

KLEIBERIT 700.5.00 Reactive hotmelt

- high adhesion to many materials

- IMO FTP Code Part 5 & Part 2

- assembly bonding

KLEIBERIT 702.5.00 Reactive hotmelt

- high initial strength, good bonding on pretreated aluminium

- IMO FTP Code Part 5 & Part 2

- profile wrapping

KLEIBERIT 706.0.00 Reactive hotmelt

- IMO FTP Code Part 5 & Part 2

- general surface lamination

KLEIBERIT 706.1.00 Reactive hotmelt

- sticks to a wide range of materials

- IMO FTP Code Part 5 & Part 2

- general surface lamination

KLEIBERIT 706.1.50 Reactive ME hotmelt

- sticks to a wide range of materials

- free of labeling

- IMO-certified

- multiple uses in ship building

- high-gloss and super matt decors

KLEIBERIT 706.4.50 Reactive ME Hotmelt

- IMO FTP Code Part 5 & Part 2

- surface lamination of materials with high restoring forces such as veneers, HPL, CPL

- impermeable materials

- shipbuilding

KLEIBERIT 711.3.00 Reactive hotmelt

- for gluing diffusion-resistant materials

- high initial strength

- IMO FTP Code Part 5 & Part 2

- general surface lamination

- laminating aluminium sandwich elements

Bookbinding

KLEIBERIT 712.3.00 Reactive ME hotmelt

- free of labeling

- high-quality catalogues, brochures, books

KLEIBERIT 712.6.00 Reactive hotmelt

- low-emission, low temperature hotmelt

- very short open time

- very high initial strength

- high-quality catalogues, brochures, books

KLEIBERIT 712.7.00 Reactive hotmelt

- low-emission, low temperature hotmelt

- high-quality catalogues, brochures, books

Special applications

KLEIBERT 700.7.00 Reactive hotmelt

- long open time

- low processing temperature

- very high heat resistance

- heavy sacks

Automotive

KLEIBERIT 703.3.33 Reaktiver Schmelzklebstoff

- monomer-reduced

- extremely high initial strength

- 3D lamination applications

- assembly bonding

KLEIBERIT 713.0.00 Reactive hotmelt

- long open time and high initial strength

- low-emission

- middle console cladding - wooden roller blinds (wood on non-wovens)

KLEIBERIT 713.4.04 Reactive hotmelt

- low-emission

- long open time

- very easy to spray

- low-emission

- long open time

- very easy to spray

- surface lamination of vehicle interiors

- surface lamination of vehicle interiors

KLEIBERIT 713.7.00 Reactive hotmelt

- low-emission

- very high initial strength

- 3D lamination applications

- installing clips / retainers

KLEIBERIT 713.7.54 Reactive ME hotmelt

- free of labeling

- excellent stability on rollers

- very high initial strength

- installing clips / retainers

- 3D lamination applications

- laminating vehicle boot floors

- laminating the back shells of seats