© Teeraphan - istockphoto.com

Adhesives for modular bedoom furniture

In the sleeping area, case furniture is ubiquitous. A large closet, bed as well as chests of drawers or bedside tables can be found in every bedroom. The core material of the furniture panels used for this consists of wood-based materials such as MDF or pressboard. For a sophisticated look, decorative materials are glued to the wide surfaces of the furniture panels. In addition, the narrow surfaces of the edges are coated with special edge bands. The choice of adhesive plays a decisive role in both surface lamination and edge banding. Durability, perfectly laminated surfaces or an edge finish with an invisible glue line define the requirements profile of the adhesive. Furthermore, ever faster and more efficient production processes demand a specially adapted adhesive formulation.

Polyurethane-based adhesives offer by far the best performance. Our reactive PUR hotmelt adhesives are also available in micro-emission quality. This enables better occupational safety. In addition, the use of these adhesive systems is more environmentally friendly compared to conventional PUR hotmelt adhesives.

© teeraphan - stock.adobe.com

© KLEIBERIT

2D surface lamination of bedroom furniture

Laminating furniture fronts

Flat furniture elements can be laminated with a huge range of decors such as real wood veneers, decorative paper films, or PET and ABS films. These are all available in different designs, with and without embossments, to provide high quality surfaces and an appealing look and feel. Large-surface industrial lamination of flat furniture panels is usually done in a flat lamination process (2D surface lamination). The adhesives applied here must have excellent processing properties, especially when used for laminating very thin films. Laminated panels are typically used for:

-

fronts

-

sides

-

rear panels

-

shelves

-

bed sides and headboards

Super matt and high-gloss decors are current trendsetters in the furniture industry. The surfaces must be mirror-smooth, also across bonded edges, as even the smallest irregularities can negatively impact the visual effect.

KLEIBERIT has a wide selection of adhesives for classic decor materials as well as for high-gloss and super matt decors. We also offer adhesives for laminating with thin films and have the expertise to optimally configurate your production process.

CompleteLine process – surface coating and edge banding in one step.

In addition to classic surface coating, we also offer tried-and-tested inline solutions for effective surface bonding and edge banding in a single run. The CompleteLine process enables extremely smooth surfaces. EVA-, APAO- or PUR-based hotmelts are applied directly to the decor paper, with the choice of adhesive depending on the heat sensitivity of the decor materials, the speed of the production process, and the performance specifications of the end product. Combinations of different adhesive systems are also possible.

Our chemical engineers and scientists are constantly researching new adhesive formulations and their processing methods. KLEIBERIT excels in tailored and customer-oriented adhesive solutions! Let us help you find the right adhesive for your needs, contributing to the most efficient production process. We draw on decades of experience in surface bonding and edge banding, and have comprehensive expertise and knowledge of standard machines and production processes. Contact us.

© onzon - stock.adobe.com

3D surface lamination of bedroom furniture

3D lamination with plastic decors

Furniture panels with 3D surfaces are often used for furniture fronts of wardrobes and sideboards, etc. The core material is usually made of MDF in all kinds of shapes and sizes, that is then 3D-laminated with PP, PVC or ABS films. Low-viscosity PUR dispersions are the most suitable adhesive for such purposes, as they are easy to spray on and ensure permanent and stable bonding of the decor material. The 3D processing method uses membrane or vacuum presses. Once the laminate and the core material have been joined, pressure and heat reactivate the adhesive, allowing the decor material to adapt perfectly to the texture of the carrier material.

© ostap25 - stock.adobe.com

3D laminating with real wood decors

Real wood veneers are usually laminated with PVAc dispersions (veneer glues). Before being pressed on, the veneer is slightly moistened to prevent any cracks or tears occurring. PUR dispersions can also be used, as they provide higher resistance to water and heat than classical PVAc veneer glues.

Contact us for advice! Our engineers have a wealth of experience in dealing with the challenges of 3D lamination. Benefit from our decades of experience.

© Teeraphan - istockphoto.com

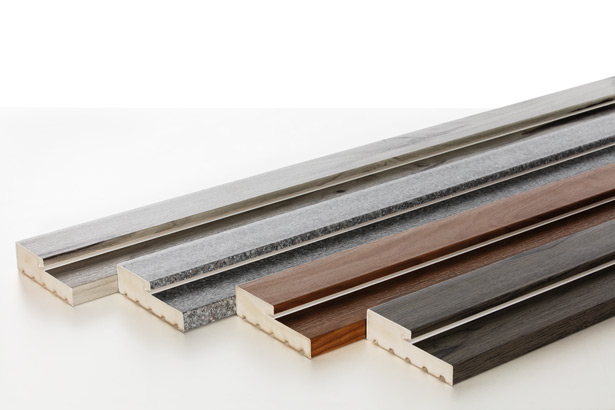

Edge banding for bedroom furniture

So-called zero bond lines are the benchmark in modern edge banding and represent top processing quality. Edge banding in the furniture industry places high requirements on the adhesives used. A wide range of material combinations and the specifics of manufacturing environments require sophisticated adhesive systems that tie in perfectly with the production process. As resistance to heat and humidity are not a major specification for bedroom furniture, EVA- and APAO-based hotmelts are generally the product of choice. Top-quality brands, however, use only PUR-based adhesives.

Here are some common material combinations for edge banding bedroom furniture:

-

MDF boards with ABS edges

-

chipboards with ABS edges

-

sandwich panels with ABS edges

-

sandwich panels with aluminium edges

-

and many more.

Every production process is different. Preferences, habits and experience determine the specifics of a production process. We have over 70 years of experience in the adhesives industry, giving us extensive know-how of standard processing methods and machines. Let our adhesive specialists help you analyze and optimize your individual edge banding processes.

To the products & consultation options. Click here.

© Andrea Becker-Weimann

© Andrea Becker-Weimann

Profile wrapping

Laminated decor skirting is a standard in bedroom furniture, and there is a huge variety of decor materials on the market. During the lamination process, air bubbles must be avoided at all costs to ensure a high-quality appearance. The adhesive used plays a decisive role here. When laminating skirting with tight radii, the adhesive must also be able to withstand the recoil strength of the decor material immediately after being glued. This requires a very high initial strength.

Reactive PUR hotmelts are the adhesives of choice for profile wrapping. Used with the right primer (when plastic or metal profiles are used), they achieve excellent bonding quality. An optimally configured wrapping line also ensures consistent bonding quality. The following material combinations are standard in bedroom furniture:

Profile materials

-

solid wood

-

wood-based materials

-

aluminium

-

plastics

Decor materials

-

CPL

-

decor paper

-

veneers

-

thermoplastic films

Our many years of experience and continuous R&D activities always keep us up to date with the latest adhesive technologies. Let our engineers help you optimize your production process. We provide adhesive systems tailored to your needs.

To the products & consultation options.

© NorGal - stock.adobe.com

Gluing dowels and furniture bodies in living room furniture

A finished piece of modular furniture has all its components joined together, generally with dowels. To achieve a high degree of stability, special dowel glues are used to attach the dowels, often mechanically with automatic dowel insertion machines. Either a very high viscosity or a low viscosity thixotropic dowel glue is used, depending on the specifications of the furniture and the related production process. Our modern dowel glues are easy to dose and provide secure adhesion over the entire lifecycle of the furniture.

Would you like a personal consultation? To the product table & consultation options.

© Ronstik - stock.adobe.com

Assembly bonding

Gluing offers clear benefits over drilling holes and inserting screws. Almost all kinds of material combinations can be glued together with the right assembly adhesive. Easy handling, high initial strength, and permanent, strong adhesion are further arguments in favor of gluing. Our PUR- and STP-based adhesives come in handy cartridges for assembly bonding uses. Typical applications of assembly bonding in bedroom furniture are:

-

gluing handles to cupboard doors or drawers

-

attaching skirting boards

-

mounting decor elements

Do you need help with a specific application? Get in touch with us for a personal consultation.

Dispersion adhesives

KLEIBERIT 332.0.00 Surface/veneer glue

- dispersion adhesive with long open time

- IMO FTP Code Part 5 & Part 2

- Minergie Eco (A + P), corresponding to 1st priority ECO-BKP

- surface bonding of laminated panels on wood-based boards

KLEIBERIT 303.0.00 White glue

- dispersion with medium open time (6-10 minutes)

- DIN EN 204 D3

- as a two component glue with 5% KLEIBERIT 303.5.00 DIN EN 204 D4

- DIN EN 14257 (Watt 91)

- FDA Guideline 21CFR § 175.105

- surface bonding of HPL and CPL to wood-based materials

- surface bonding (veneer on wood-based materials)

- surface bonding of laminated panels

- gluing mortise joints

- dowel gluing

- gluing furniture bodies

KLEIBERIT 308.0.00 Lacquer glue

- dispersion adhesive for varnished surfaces

- bonding wood-based materials to varnished surfaces

KLEIBERIT 316.0.00 Dowel glue

- non-blocking PVAc dispersion for use with doweling machines with injection nozzles

- gluing furniture bodies with automatic dowelling machines

- knot-sealing machines

KLEIBERIT 347.0.00 PVAc glue

- dispersion with short open time (3-4 mins)

- IMO FTP Code Part 5 & Part 2

- stationary postforming process, multi-layer molded wood manufacturing, surface lamination, edge banding, furniture body gluing

KLEIBERIT 430.7.00 1C PUR dispersion adhesive

- single-component, with integrated hardener

- 3D film lamination for all standard films

KLEIBERIT 431.7.00 1C PUR dispersion adhesive

- THE high-gloss expert

- suitable for automated spraying systems

- FIRA certified according to BS 6222 Part 3 1999

- 3D film lamination for high-gloss and thin films

KLEIBERIT 433.2.00 Supratherm - 2C PUR dispersion adhesive

- all-round product for all standard deep-drawing processes

- 3D film lamination for all standard films, usable with or without a hardener

KLEIBERIT 436.3.00 2C PUR dispersion adhesive

- laminating dispersion for temperature-sensitive materials (for deep-drawing)

- 3D film lamination for all standard films, usable with or without a hardener. Very high heat resistance

EVA hotmelts

KLEIBERIT 773.3.00 Hotmelt

- transparent glue joint

- for high feed rates

- high initial strength

- gluing all kinds of standard edging materials

KLEIBERIT 773.8.00 Hotmelt

- for high feed rates

- high initial strength

- also for solid wood and veneer edges

- gluing all kinds of standard edging materials

KLEIBERIT 774.4.00 Hotmelt

- for all standard edge banding materials

- good initial strength

- gluing all kinds of standard edging materials

KLEIBERIT 777.0.00 Hotmelt

- high heat resistance

- gluing all kinds of standard edging materials

KLEIBERIT 779.6 Hotmelt

- also for solid wood and veneer edges

- good initial strength

- available in white, ivory, medium brown and black

- gluing all kinds of standard edging materials

- edge banding with HolzHer machines

KLEIBERIT 782.0 Hotmelt

- HolzHer cartridge

- available in white, ivory, mahogany and black

- edge banding with HolzHer machines

Solvent-based adhesives

KLEIBERIT 114.5.00 Solvent adhesive

- high initial strength

- surface bonding of veneers, plastic films, laminates, and inorganic coating materials on wood-based boards

KLEIBERIT 261.7.00 Polyester adhesive

- can be applied with doctor blades, fast-drying

- surface lamination of plastic and paper films on wood-based materials

Assembly adhesives

1C PUR assembly adhesive 568.1.00

- all-round adhesive for use on building sites

- high-strength bonding, open time approx. 3 mins

- DIN EN 204 D4

- all types of assembly bonding

KLEIBERIT 568.0.00 1C PUR assembly adhesive

- all-round adhesive

- suitable for glass

- open time appox. 5 mins

- DIN EN 204 D4

- all types of assembly bonding

KLEIBERIT 569.0.00 1C PUR assembly adhesive

- stable on porous substrates

- DIN EN 204 D4

- all types of assembly bonding

KLEIBERIT 600.0.00 1C STP assembly adhesive

- low-emission, long-term elasticity, transparent

- elastic gluing of glass, wood, metal, etc.

KLEIBERIT 601.1 1C STP assembly adhesive

- low-emission

- available in white, beige and black

- very low emission (EC1 plus R) according to EMICODE classification

- all types of assembly bonding

Polyolefin hotmelts

KLEIBERIT 753.5.00 Hotmelt

- high temperature resistance

- suitable for roller, slot nozzle and CNC machines

- straight edges

- postforming

- soft forming

KLEIBERIT 754.1.00 Hotmelt

- for feeding speeds up to 80m/min

- straight edges

- postforming

- soft forming

New products

KLEIBERIT 601.1 1C STP assembly adhesive

- low-emission

- suitable for natural stone

- available in white, beige and black

- very low emission (EC1 plus R) according to EMICODE classification

- attaching drawer and cupboard door knobs and handles

- all types of assembly bonding

- repair gluing

KLEIBERIT 706.4.54 Reactive hotmelt

- high initial strength

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, CPL

KLEIBERIT 707.9.85 Reactive ME hotmelt

- no hazard labeling required, contains renewable raw materials

- for industrial equipment with higher feeding speeds

- versatile edge banding on furniture boards (fronts, rear and base panels, sides)

KLEIBERIT 736.2.00 Reactive hotmelt

- revolutionary, isocyanate-free reactive hotmelt

- sticks to a very wide range of materials

- low processing temperature

- general surface lamination

Reactive PUR hotmelts

KLEIBERIT 702.5.59 Reactive ME hotmelt

- free of labeling

- fluorescent

- profile wrapping

KLEIBERIT 706.0.05 Reactive hotmelt

- excellent running properties, sticks to a wide range of materials

- good surface properties

- surface lamination

- very suitable for thin papers and films

KLEIBERIT 706.1.50 Reactive ME hotmelt

- highest surface quality

- free of labeling

- IMO FTP Code Part 5 & Part 2

- general surface lamination

- high-gloss and super matt decors

KLEIBERIT 706.2.03 Reactive ME hotmelt

- free of labeling

- profile wrapping

- general surface lamination

KLEIBERIT 706.2.50 Reactive ME hotmelt

- free of labeling

- excellent high-gloss properties

- general surface lamination

KLEIBERIT 706.4.00 Reactive hotmelt

- very high initial strength

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, CPL

KLEIBERIT 706.7.00 Reactive hotmelt

- very high initial strength

- excellent adhesion to HPL

- surface lamination of cover materials such as HPL, CPL

KLEIBERIT 706.7.50 Reactive ME hotmelt

- free of labeling

- high initial strength

- excellent adhesion to HPL

- surface lamination of cover materials such as HPL, CPL

- impermeable materials, e.g. HPL

KLEIBERIT 707.9.40 Reactive hotmelt

- highest possible initial strength

- ideal for CNC machines

- versatile edge banding on furniture boards (fronts, rear and base panels, sides)

KLEIBERIT 707.9.50 Reactive ME hotmelt

- free of labeling

- for industrial equipment with higher feeding speeds

- versatile edge banding on furniture boards (fronts, rear and base panels, sides)

KLEIBERIT 707.9.85 Reactive ME hotmelt

- no hazard labeling required, contains renewable raw materials

- for industrial equipment with higher feeding speeds

- versatile edge banding on furniture boards (fronts, rear and base panels, sides)

KLEIBERIT 709.1.00 Reactive hotmelt

- excellent adhesion to inorganic materials

- surface lamination of mineral materials (e.g. stone veneers), metal, and glass

KLEIBERIT 709.3.00 Reactive hotmelt

- very high surface smoothness and quality

- high-gloss decors

- super matt decors

KLEIBERIT 711.0.52 Reactive ME hotmelt

- light-fast product

- surface lamination of transparent plastic films with suitable adhesion promoter on the adhesive side

KLEIBERIT 711.2.00 Reactive hotmelt

- plastics specialist

- surface lamination of various plastic films

KLEIBERIT 711.3.00 Reactive hotmelt

- for gluing diffusion-resistant materials

- high initial strength

- IMO FTP Code Part 5 & Part 2

- general surface lamination

KLEIBERIT 711.3.37 Reactive ME hotmelt

- no hazard labeling version of 711.3.00

- general surface lamination

KLEIBERIT 711.9.00 Reactive hotmelt

- long open time

- extremely high initial strength

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, etc.

- honeycomb plate panelling

KLEIBERIT 711.9.06 Reactive hotmelt

- for porous and pressure-sensitive materials

- very high initial strength

- surface lamination of materials with high recoil strength, e.g. veneers, HPL, etc.

- honeycomb plate panelling

KLEIBERIT 716.8.50 Reactive ME hotmelt

- product free of labeling

- plasticizer stable

- excellent bonding to plastics

- general surface lamination

- surface lamination of plasticized materials on carrier boards

1C PUR adhesives

KLEIBERIT 501.0.00 1C PUR adhesive

- medium open time

- DIN EN 204 D4

- DIN EN 14257 (Watt 91)

- IMO FTP Code Part 5 & Part 2

- surface bonding of HPL and CPL to wood-based materials

- surface bonding of mineral materials and rigid foams

- surface bonding of laminated panels

- manufacturing furniture with high moisture resistance specifications

KLEIBERIT 501.4.00 1C PUR adhesive

- very short open time

- DIN EN 204 D4

- DIN EN 14257 (Watt 91)

- fast assembly and repair gluing with high temperature and moisture resistance

KLEIBERIT 501.6.00 1C PUR adhesive

- long open time

- DIN EN 204 D4

- DIN EN 14257 (Watt 91)

- surface bonding of laminated panels

- surface bonding of HPL and CPL to wood-based materials

- manufacturing furniture with high moisture resistance specifications

- gluing frame corners made of all common types of wood for windows

KLEIBERIT 501.8.00 1C PUR adhesive

- short open time

- DIN EN 204 D4

- DIN EN 14257 (Watt 91)

- DIN EN 12765 C4

- manufacturing furniture with high moisture resistance requirements

- surface bonding of HPL and CPL to wood-based materials

- gluing frame corners made of all common types of wood for windows